Manufacturing

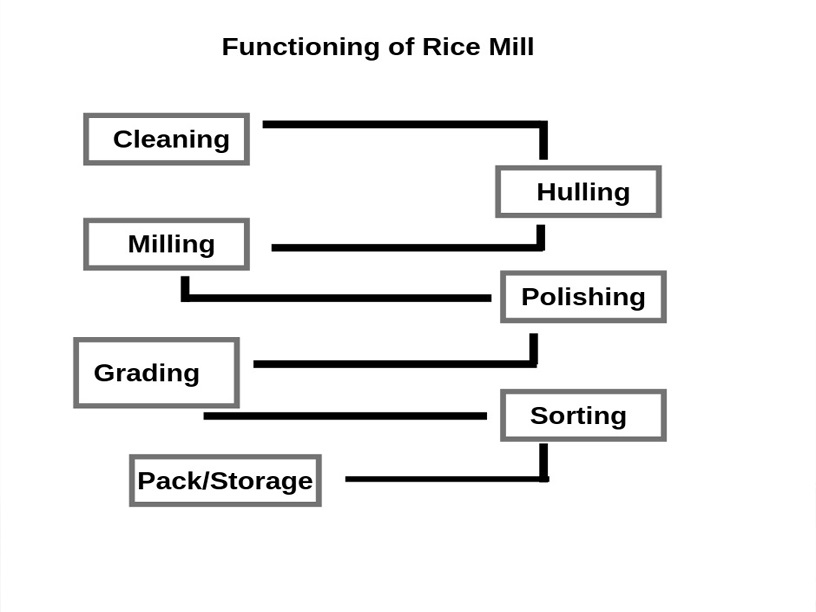

At [Subhmani Agro PVT. LTD./ Lakho Infra PVT. LTD.]., we are dedicated to delivering the finest quality rice through a carefully managed production process. From selecting premium grains to the final stages of packaging, every step is carried out with precision to preserve freshness, purity, and nutritional value. Our commitment begins with sourcing high-grade paddy from trusted farmers who follow best agricultural practices. Each grain undergoes thorough cleaning, milling, and processing using advanced technology to ensure superior quality. We prioritize hygiene and maintain strict quality control standards at every stage of production.